GREASE INTERCEPTOR CLEANING IN EVERETT

Everett Grease Interceptor Cleaning

Grease Interceptor Cleaning Services in Everett

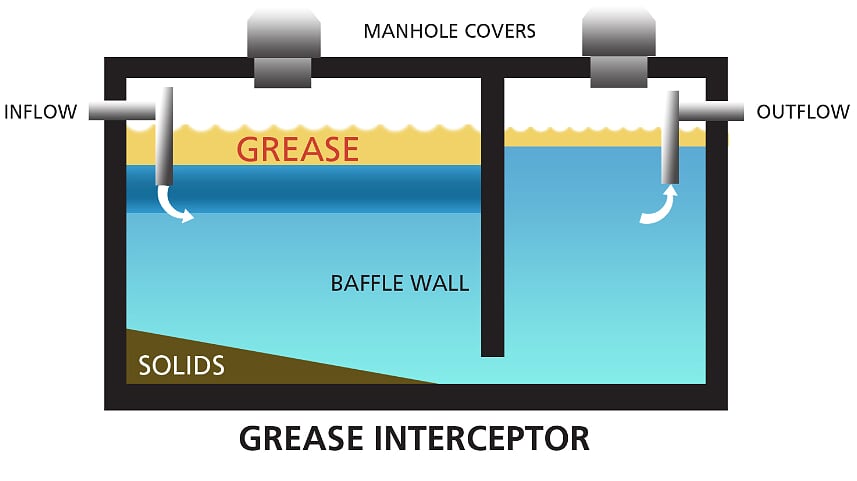

Fats, oils, and grease that are poured down building drains cause serious clogs in normal drain traps, drain piping, sewer piping, public sewers, and pumping stations. Gravity operated grease traps (GGI) use multiple compartments to slow the flow of wastewater to allow solids and grease to separate. At higher temperature than the hydro mechanical trap, FOGs in a gravity operated grease interceptor float in the upper area of the trap where they are trapped by one or more baffled compartments with solids (grit, dirt) settling to the trap bottom. Through the use of the gravity method about 90% of FOGs can be removed from wastewater, but adequate space is required for these devices. You can never go wrong with our grease interceptor cleaning service!

Hydro mechanical grease interceptors rely on a process of cooling wastewater to allow heavier FOG to settle to the trap bottom for collection and cleaning. The capacity of hydro mechanical grease traps is rated in pounds (capacity) and flow rate (gallons per minute). These interceptors use the physical principle that fats, oils and grease are lighter than water and will rise to the top of a water surface and heavy debris will fall to the bottom of the trap when the mixture is allowed to stand for a period of time.

The longer the wastewater stays in the trap, the better the separation. But as the amount of retained grease and solids increases, the effective volume of the trap decreases, retention time decreases and physical separation decreases, resulting in a pass-through of solids, fats, oils and grease.

For a grease interceptor to work properly it must be located sufficiently far from the hot water source that the wastewater entering the trap will be cool enough that the trap can in fact do its job.

The cleaning frequency depends on grease interceptor size or capacity, type, wastewater flow, and local regulations. If the FOG and food solid content of the grease trap is greater than 25%, then the grease trap must be cleaned every week, or as frequently as needed to prevent 25% of liquid capacity displaced by FOG and food solids.

The pumping and cleaning process

Attempting a DIY venture on grease trap cleaning is a bad idea, because without the proper tools and equipment, it can put your health and life at risk. Restaurant owners almost always hire professional grease trap cleaning services with a professional licensed and bonded team. Regular cleaning and maintenance is essential for a commercial grease trap to operate properly and efficiently!

Here is a sample of typical regulations governing the cleaning of a grease interceptor:

The user is responsible for ensuring that grease control devices are operated and maintained properly at all times, at no expense to the city.

Grease interceptors must be cleaned on a regular basis, at a frequency so that the combined grease and solids accumulation does not exceed 25 percent of the total liquid depth of the interceptor. But cleaning can’t happen less frequently than once every three months while the establishment is in operation, except as approved by the city. Cleaning will consist of removal by a licensed commercial waste hauler of the entire contents of the device, including liquids and solids.

Grease traps, both manual and electromechanical, must be cleaned on a regular basis, no less than once per week. Additionally, grease traps should be visually inspected regularly to check for leaking seams and pipes, and effective operation of baffles and flow regulating devices.

Waste materials from grease control devices shall not be, under any circumstances, discharged to the sanitary sewer system. Flushing a grease control device with hot water is prohibited.

Keeping tabs on the waste content of your grease interceptor

Large fast food chain restaurants have learned that when it comes to grease interceptors, the bigger, the better, due to the massive volumes of FOG waste that must be processed each day. The primary reason for a grease interceptor installation is to trap all FOG wastes in the passing water, which otherwise would contaminate the city sewer system with negative results. For this reason, it’s imperative to strictly follow a regular schedule with regards to pumping and cleaning. A brand new or newly cleaned grease interceptor operates at its highest efficiency since it begins free from any waste which interferes with the processing.

The grease interceptor chambers trap the greasy waste by taking advantage of the fact that it’s not as heavy or as dense as water, so it will easily separate. The volume of the most commonly used grease interceptor is 750 gallons with the volume of the larger tanks up to 3000 to 4000 gallons. Large fast food chain food serving establishments use grease interceptors with a volume as high as 5000 gallons. Any failure or overflow could mean an emergency shutdown which could be financially ruinous.

Of course, a waste level of 100% would be a disaster and met with a heavy fine and possibly other actions by the authorities. The Everett health and safety regulations mandate that this level cannot go above 30%, because once the level goes beyond that limit, incidents of an overflow increase exponentially. Whenever we perform any service on your grease interceptor, we take note of the waste level and the amount of time that has passed since the last service. Soon a trend can be observed which will allow us to know in advance what the waste level will be.

Affordable & Reputable Grease Trap Services